Recognoil® Products

With Recognoil® products, you can verify that your processes are actually working and that the surface of the parts meets the requirements for further processing. production efficiency.

Recognoil® 2W

The Recognoil® 2W handheld wireless surface contamination detector is a great tool for detecting surface contamination with contaminants such as grease, preservatives and lubricants, dust, cutting or cooling fluids, and other substances that come in contact with parts in during their production. The detection itself is based on the principle of inducing fluorescence of contaminants using UV radiation and capturing it using a highly sensitive detector. but also the evaluation of the suitability of the surface for subsequent technological operations.

Recognoil® 2W is commonly used to check the condition of the surface, especially before painting, electroplating, PVD and CVD coating, welding, soldering, gluing or intentional application of oil films during lubrication and preservation.

Wireless handheld device

Suited for planar surfaces

Inspect parts easily and quickly

Production, laboratory and exterior

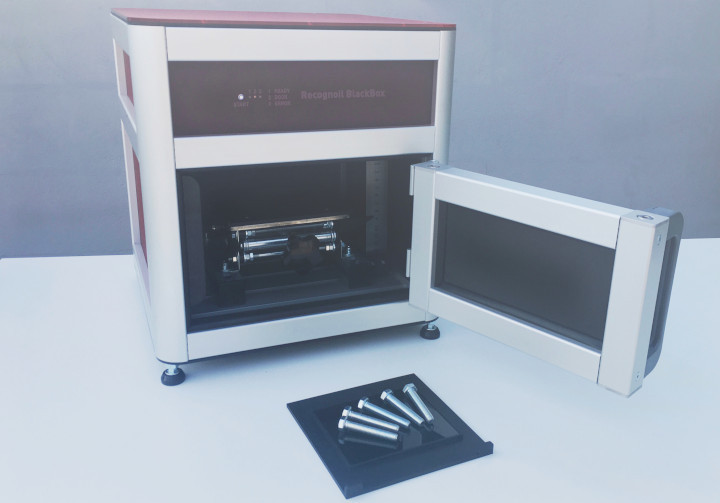

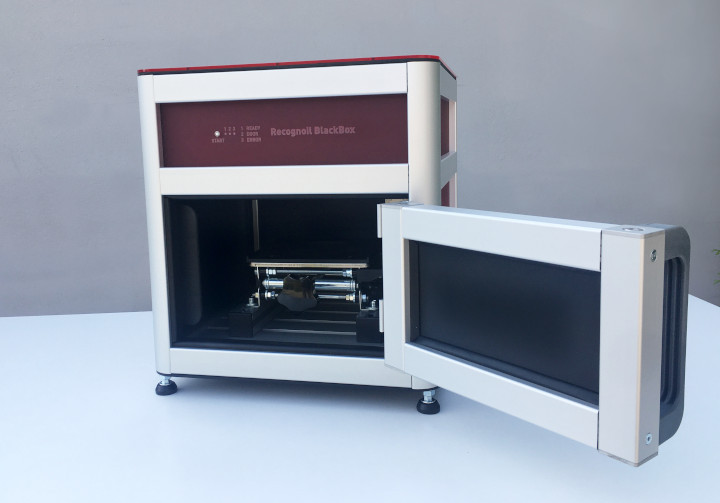

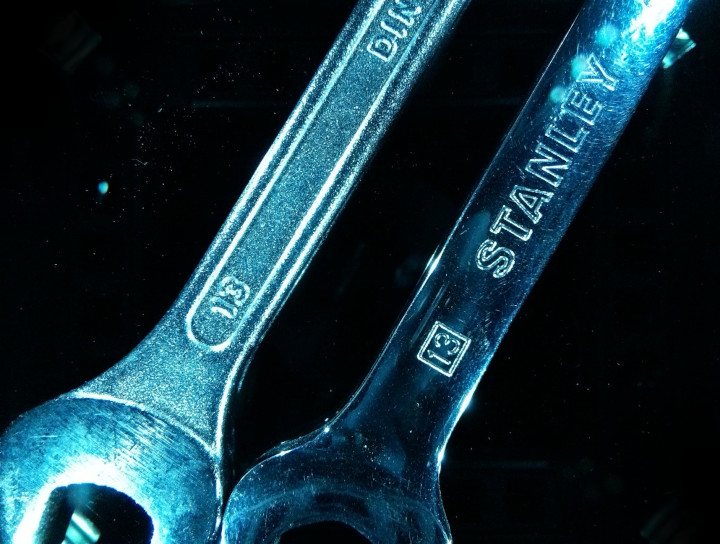

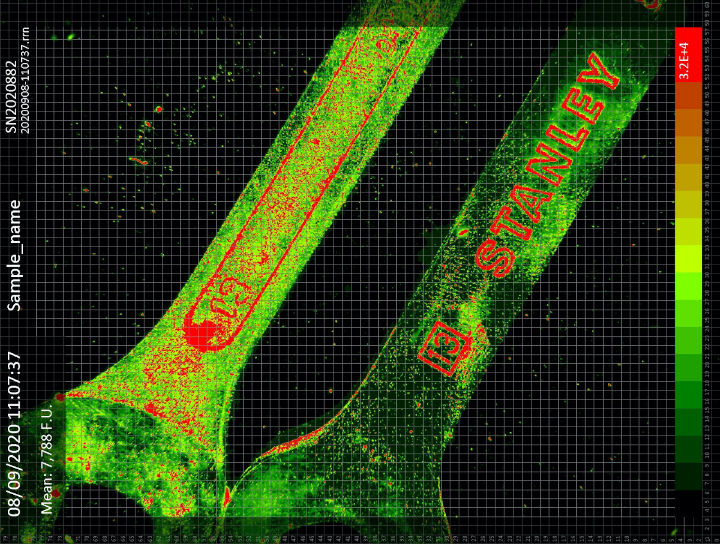

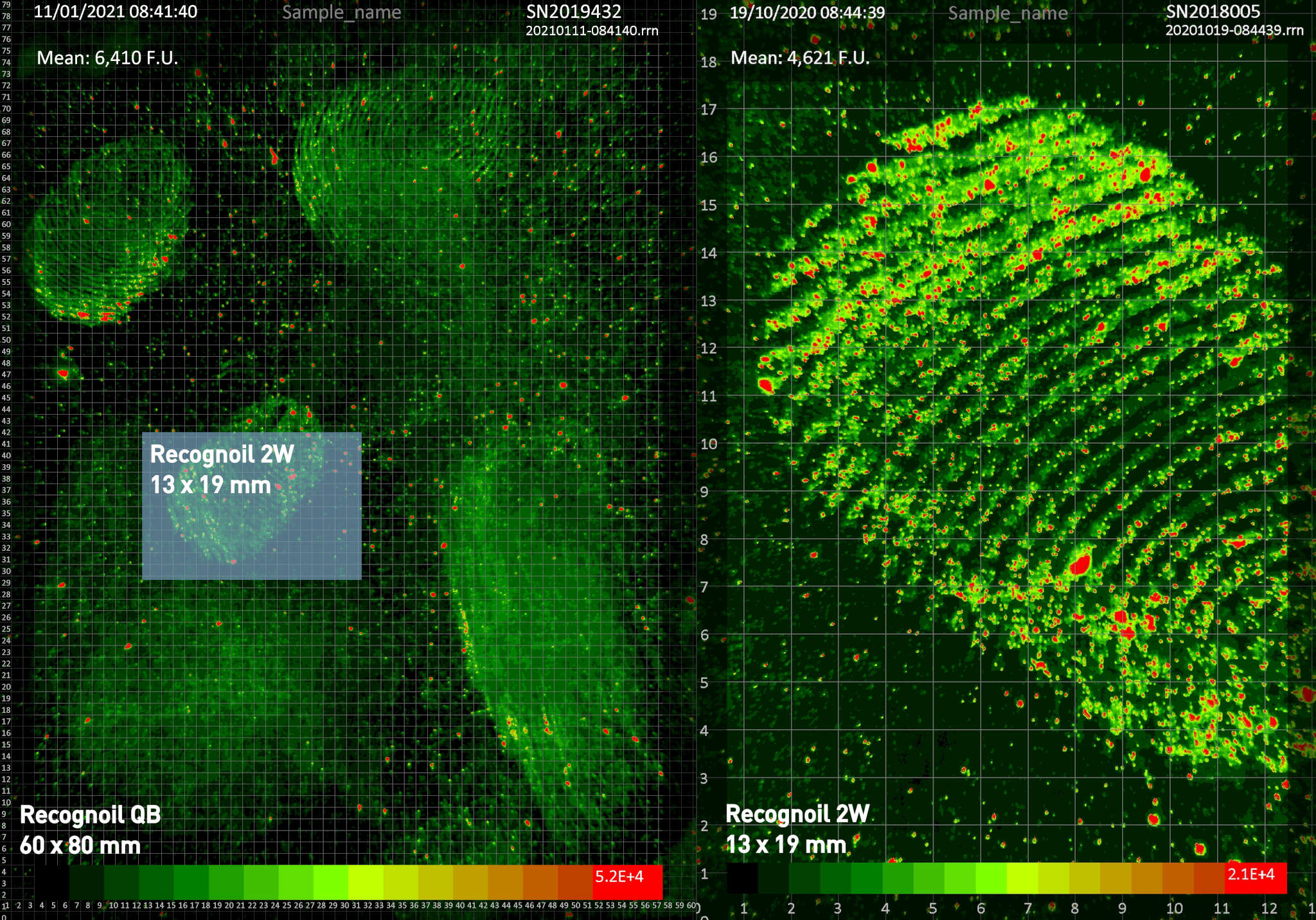

Recognoil® QB

Recognoil® QB is a desktop detector of surface contamination of parts. Objects placed on the measuring table in the box space

are irradiated with 24 powerful UV LED emitters. This induces the fluorescence of contaminants, which is captured by a sensitive detector.

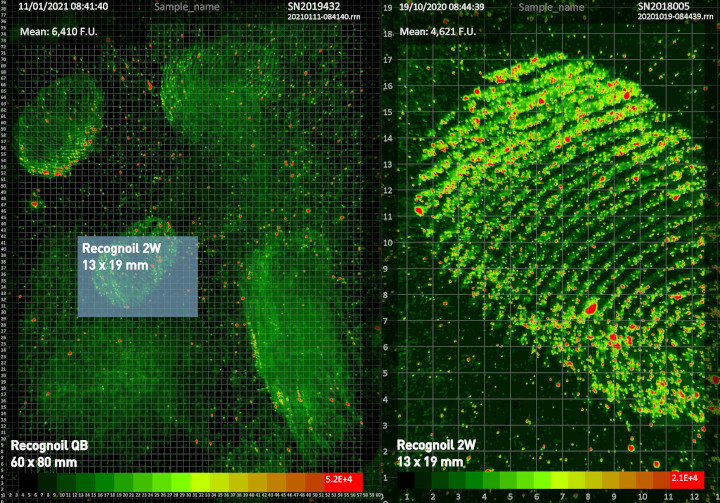

The rated area is 20 times larger than the Recognoil® 2W and is 60 x 80 mm. dirt and perfect documentation of part contamination.

The whole process of scanning parts is completely contactless, fast and does not require any surface preparation of the part.

With the help of the supplied software, it is also possible not only to visualize this data, but also to perform statistical and decision analysis (OK / NOT OK),

create protocols or even measure the thicknesses and surface concentrations of oil films.

In addition, the device can be connected to the corporate network to connect to existing quality control systems.

The construction of the device is modular and can be supplied in several different dimensions.

In addition, the function and appearance of the software can be customized according to customer requirements

Modular laboratory device

Great for complex parts

Quick localization of contamination

Easy connectivity

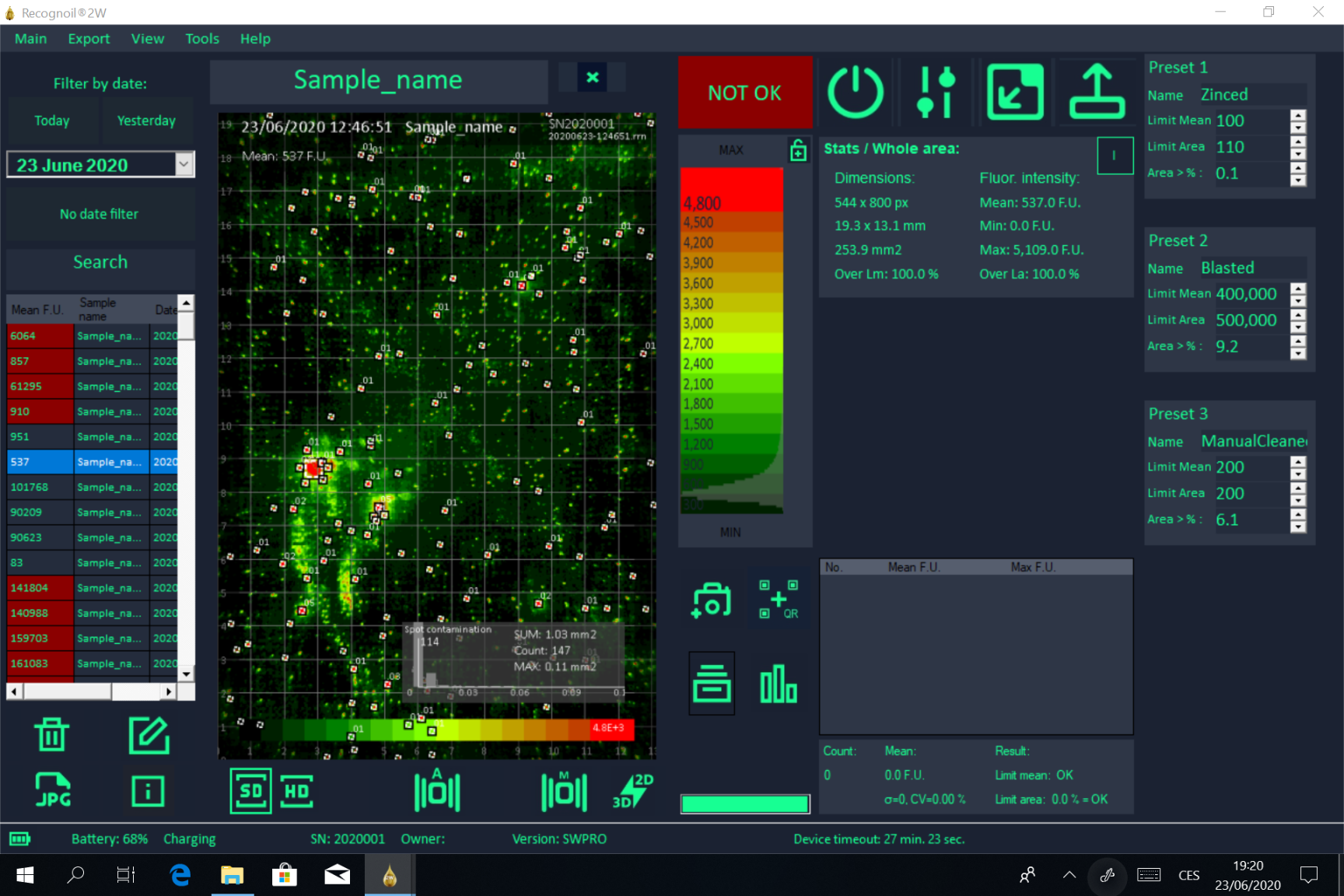

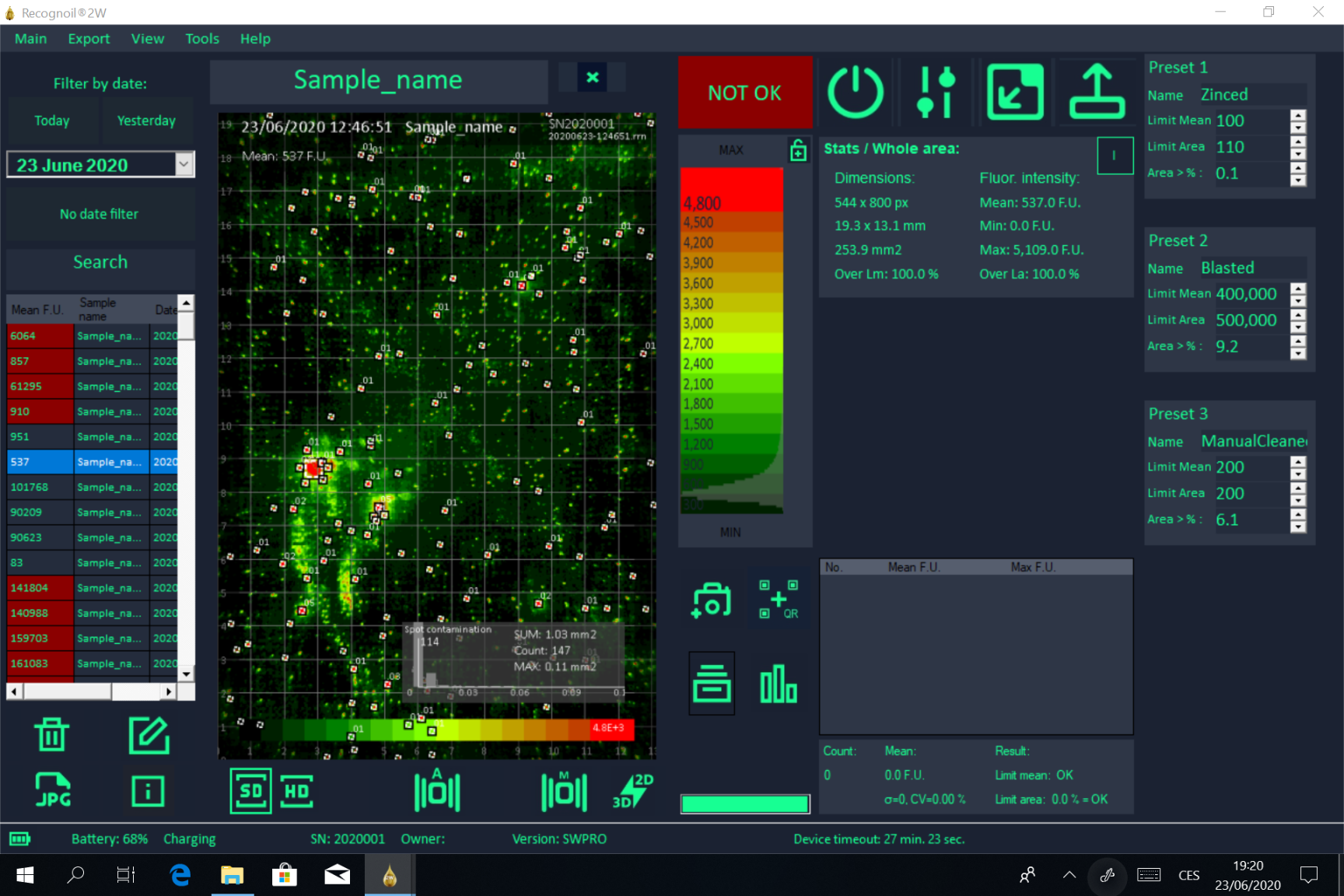

Recognoil® PRO Software

All Recognoil® devices come with advanced PRO software, which not only displays the scanned and evaluated areas, but also allows further data processing and contains a number of unique functions.

Basic functions of Recognoil® PRO software:

* additional service

2D Image output

3D Graphic output

Statistics

Easy reports

Precise measurement

Limit presets

Process Optimization

Scan history

Technical Specifications

Recognoil® 2W

Device name: Recognoil® 2W

Detection method:non-destructive, optical - contactless (the device is placed onto the surface of the object)

Function principle: excitation of impurities by UV radiation and evaluation of the image of their fluorescence intensities

UV wavelength / power: 365 nm / 1,500 mW

Dimensions of the device: 130 x 212 x 34 mm

Evaluated area size: 20 x 13.8 mm

Maximum measured object size: not limited

Scan chip resolution: 1536 x 1056 px / 1 px corresponds to approximately 13 μm

Measurement and evaluation time: 1 to max. 10 seconds, depending on the type of greasy dirt and the properties of the base material

Detection limit: minimum area concentration approx. 15 to 70 mg.m 2

(approx. 16 to 77 nm layer thickness), depending on the type of greasy impurity and

roughness of the base material, the range can be freely adjusted to a layer thickness of up to approx. 4 - 10 μm

Maximum voltage: 9V DC

Battery: built-in Li-Ion 3.7V / 3,400 mAh, endurance 700 detections without recharging (depending on exposure time)

Battery charging: with USB-Mini max. 500 mA

Hardware required: PC / laptop / tabletPC with Windows 7/8/10, not for Android and Mac

Supplied software: Recognoil® PRO - desktop application for MS Windows for operation, setup, evaluation and data management

Data interface type: wireless, WiFi - Recognoil® 2W handheld is an access point to which a tablet / laptop / PC connects

Device weight: 356 g

Material of the device body: PETG, PLA, PA6, the device body is made using 3D printing

Scope of delivery: durable case IP67, Recognoil® 2W device, Recognoil® PRO Software, blow balloon, measuring adapter, cover adapter, rubber sleeves, mini-USB charger, 10" TabletPC with durable rubberized cover, tablet charger, user manual, measurement guide with Recognoil® 2W, calibration protocol

Certification: CE - download document

Manufacturer: TechTest, s.r.o.

Country of Origin: Czech Republic (European Union)

Recognoil® 2W - Technical Specification.PDF

Recognoil® QB

Device Name: Recognoil® QB

Detection method: non-destructive, optical - completely contactless

Function principle: excitation of impurities by UV radiation and evaluation of the image of their fluorescence intensities

UV wavelength / power: 365 nm / 10,000 mW

Dimensions of the device: 330 x 330 x 330 mm (basic version), the size of the device can be increased according to customer requirements for an additional fee

Size of the evaluated area: 80 x 60 mm

Maximum size of the measured object: 250 x 250 x 150 mm (basic version), the size of the space for the scanned object can be increased at an additional cost according to customer requirements

Scan chip resolution: 1632 x 1232 px. / 1 px. corresponds to approximately 50 μm (SD), 3264 x 2464 px., 25 μm (HD)

Measurement and evaluation time: 1 to max. 10 seconds, depending on the type of greasy dirt and the properties of the base material

Detection limit: minimum area concentration approx. 15 to 70 mg.m-2

(approx. 16 to 77 nm layer thickness), depending on the type of greasy impurity and

roughness of the base material, the range can be freely adjusted to a layer thickness of up to approx. 4 - 10 μm

Maximum voltage: 24V DC

Power supply: powered by 230V AC external adapter

Required hardware: PC / laptop / tablet with Windows 7/8/10, not for Android and Mac

Supplied software: Recognoil® PRO - desktop application for MS Windows for operation, setup, evaluation and data management

Data interface type: wireless, WiFi - Recognoil® 2W handheld is an access point to which a tablet / laptop / PC connects

Device weight: 13 kg

Material of the device body: Al, PMMA, PETG, aluminum modular system allows the construction of the device according to customer requirements

Scope of delivery: Recognoil® QB, Recognoil® PRO Software, blower balloon, measuring table with manual positioning, power adapter, LAN data cable , user manual, measurement guide with Recognoil® QB, calibration protocol

Certification: CE - download document

Manufacturer: TechTest, s.r.o.

Country of Origin: Czech Republic (European Union)

Recognoil® QB - Technical Specification.pdf

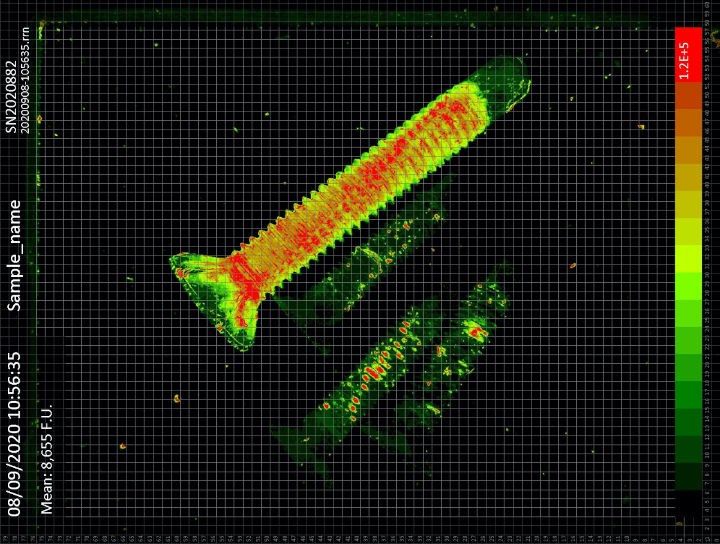

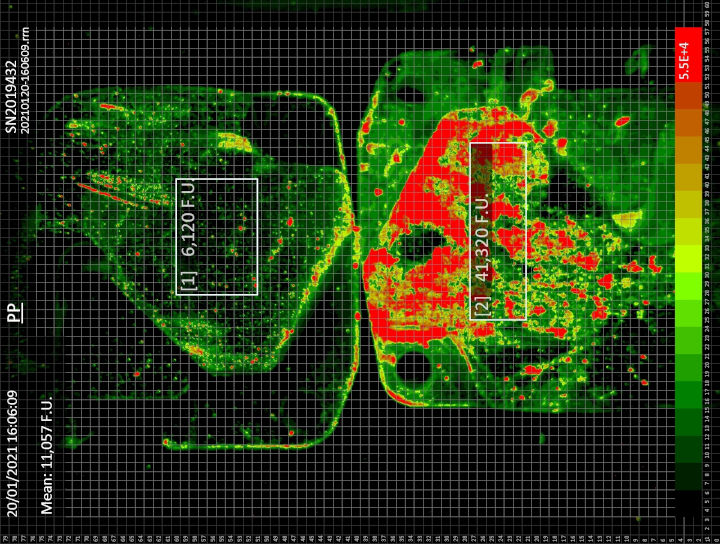

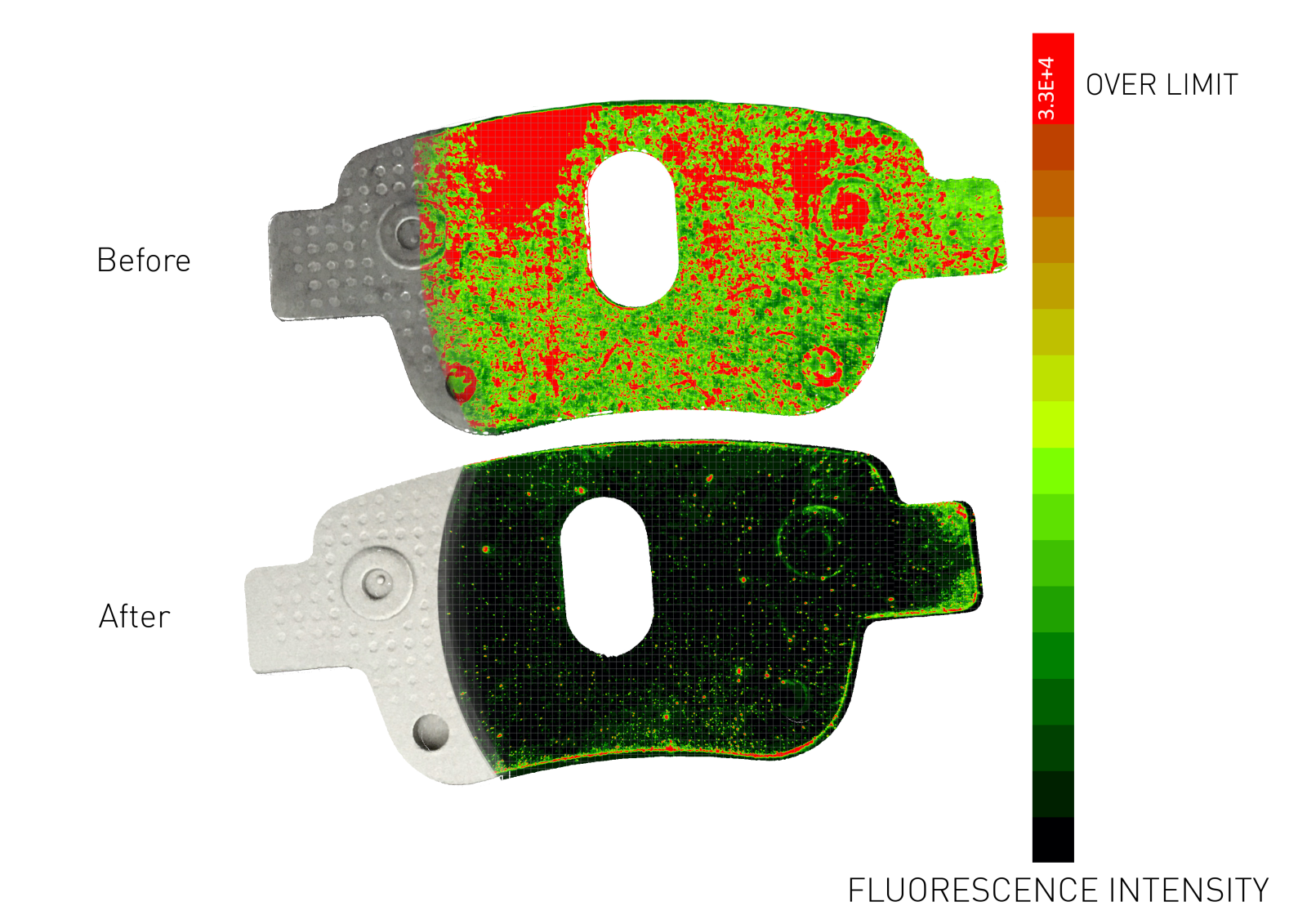

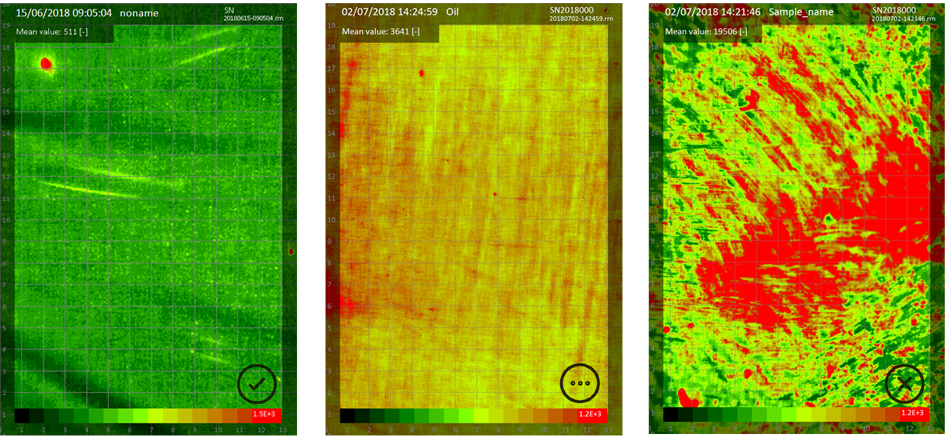

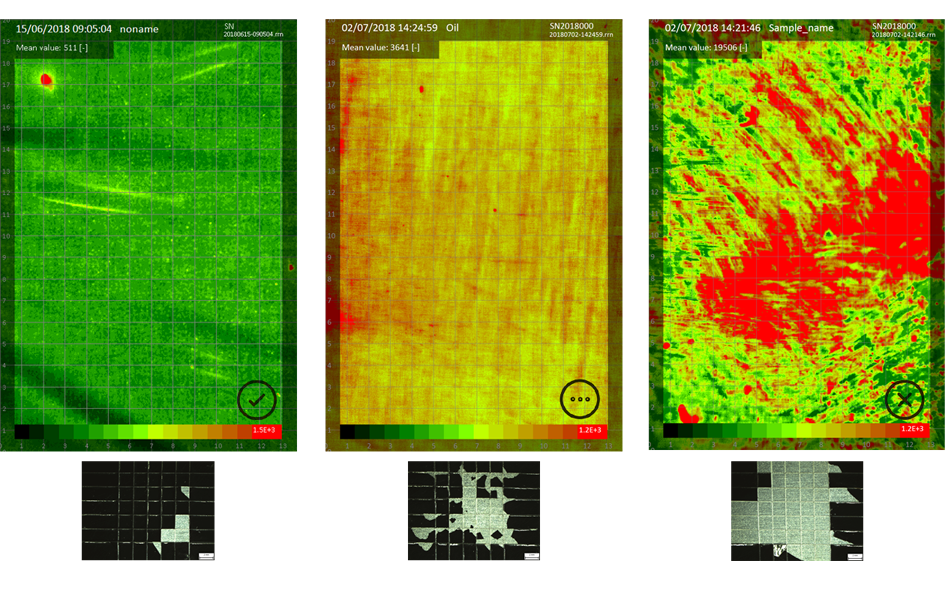

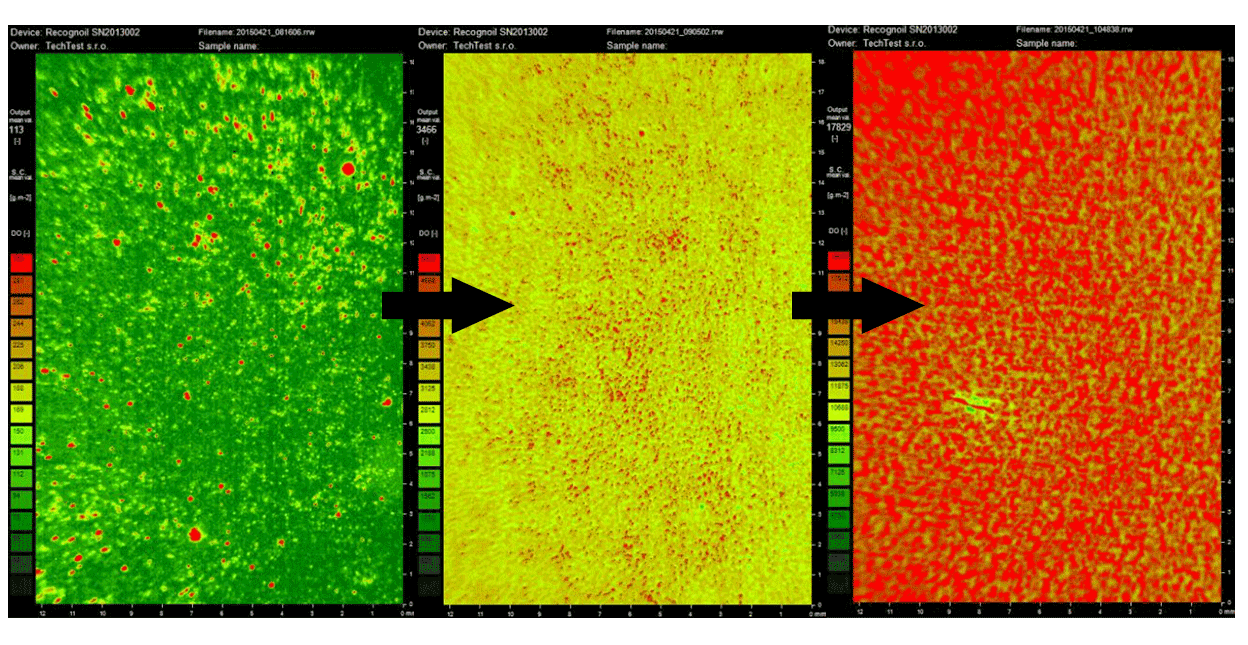

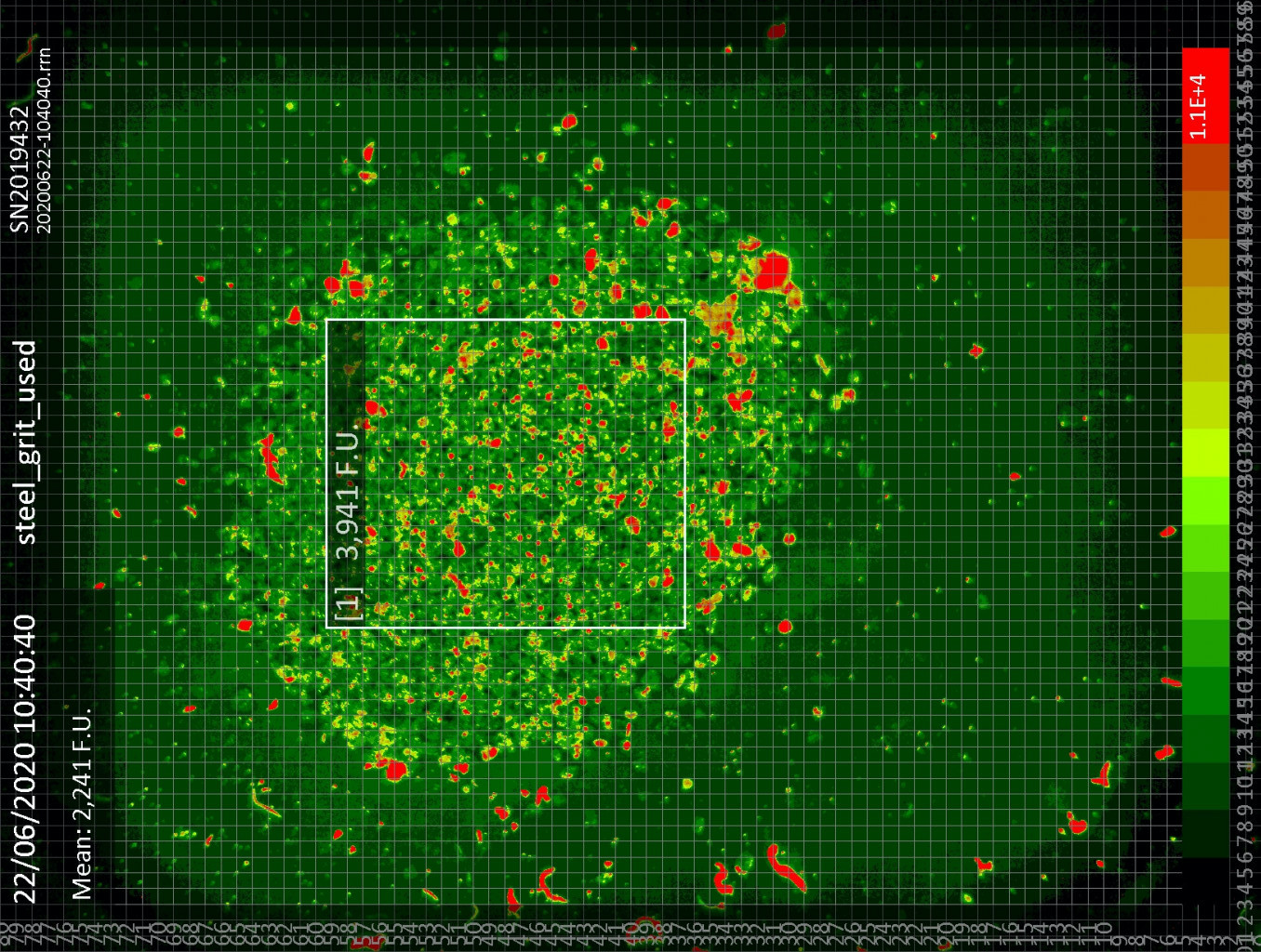

Checking the cleanliness of the surface

Recognoil® products are primarily intended for checking the surface condition of metal objects.

When checking the cleanliness of the surface, for example after the process of degreasing, blasting, plasma treatment, tumbling, etc., they are a guide for determining the quality

surface value of the fluorescence intensity detected by a particular Recognoil® instrument. The lower the measured value of fluorescence intensity, the cleaner the surface.

In this way, the parameters of the cleaning process can be optimally set so that the required degree of surface cleanliness is achieved depending on

on other technological steps or intended applications.

High surface cleanliness is important not only before making surface

modifications (coatings, powder plastics, galvanic plating, anodizing, CVD and PVD coatings, hot-dip galvanizing, metallization, etc.),

but also before gluing, welding or soldering.

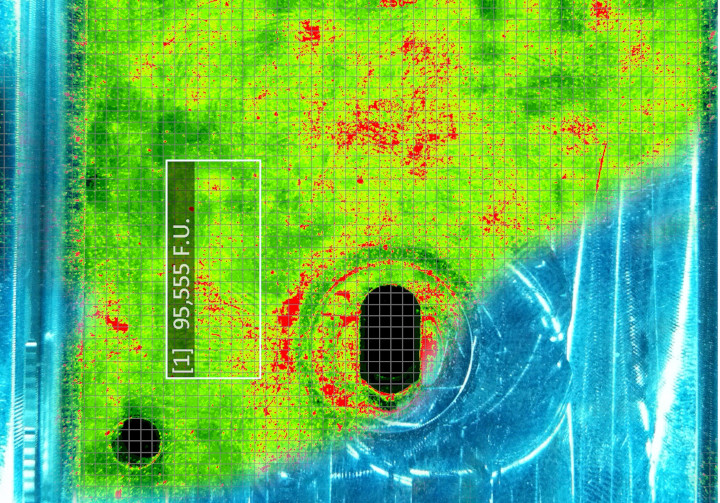

If the user defines the maximum permissible limit of the fluorescence intensity value,

thus, it immediately determines from the fluorescence map which areas are above-contaminated. If the percentage of such areas exceeds the permissible limit,

Both the SW and the device automatically evaluate the given measurement as NOT OK. The user is notified of this fact both visually and acoustically.

Thanks to surface scanning of the controlled area and visualization of fluorescence intensity values in the color spectrum of the fluorescence map, even small impurities can be immediately located and thus verify the suitability of the surface for further operations.

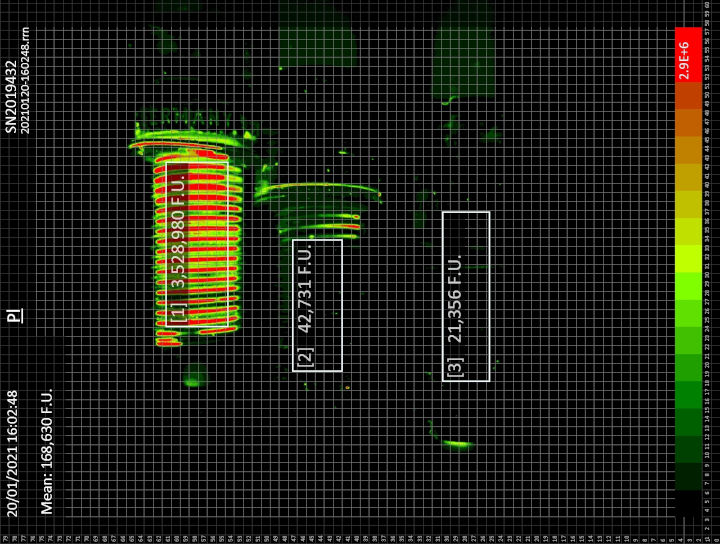

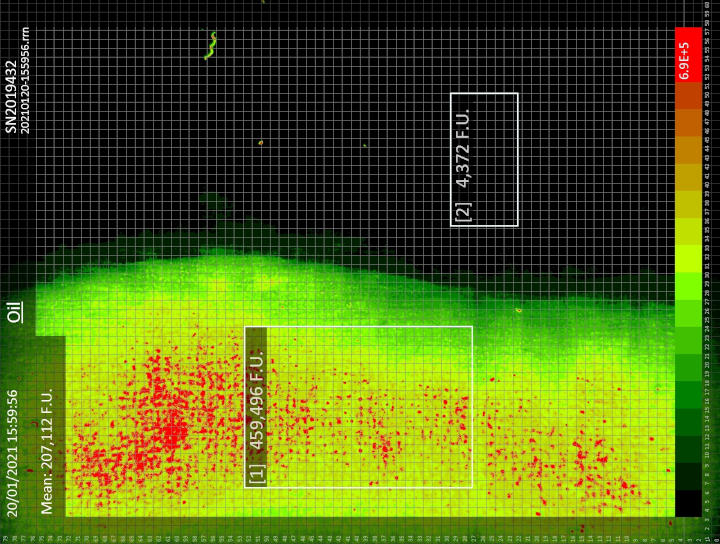

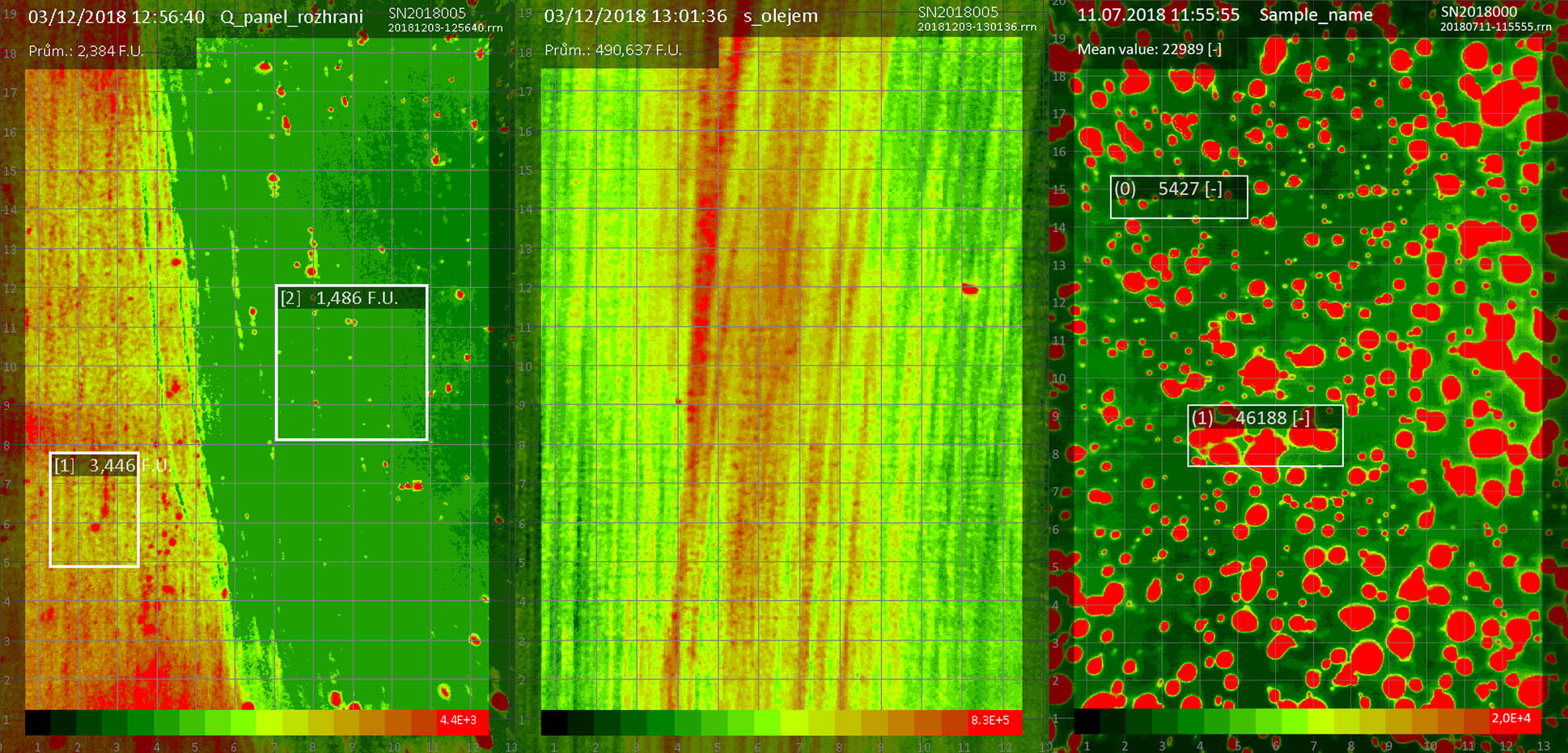

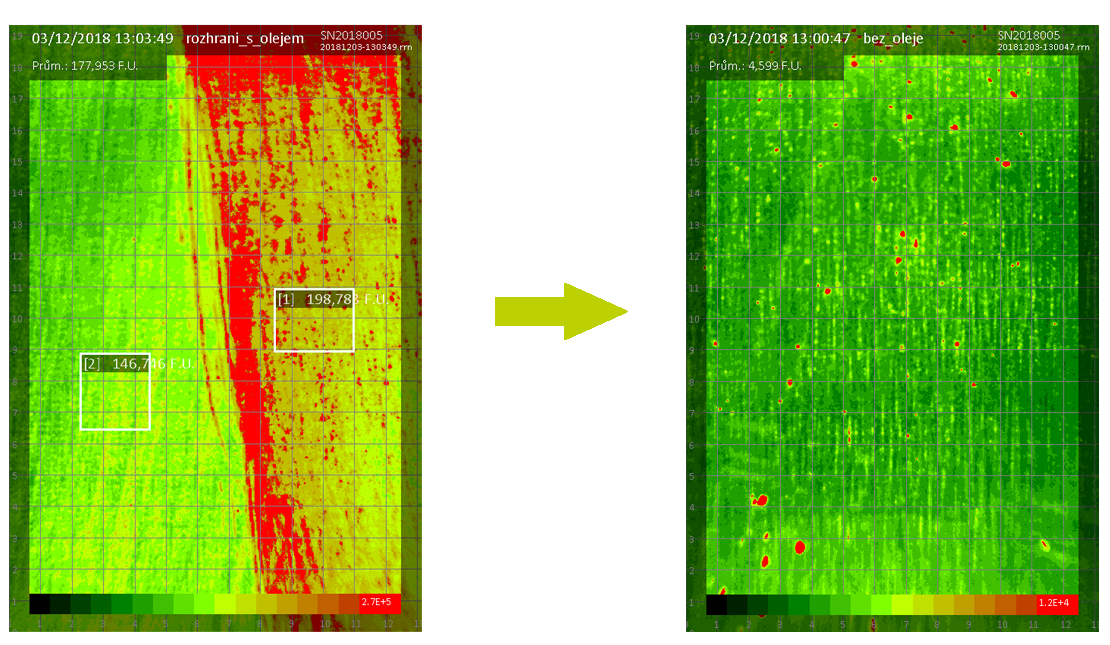

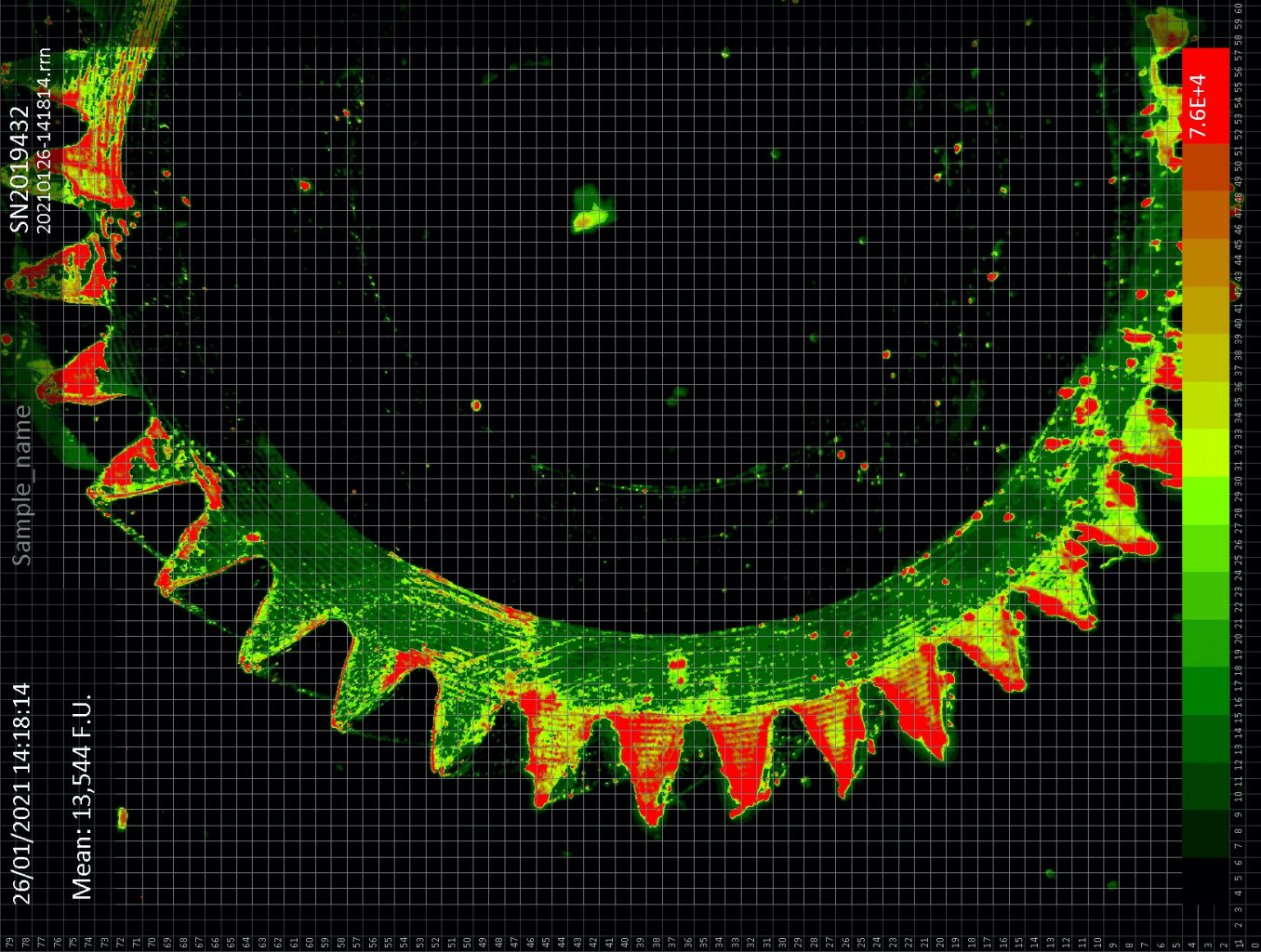

Oil & grease deposition check

Recognoil® products are a handy tool for controlling the application of an even layer of either an oil film or another product (eg passivation).

In contrast to the surface cleanliness control, in this case the application of the layer is demonstrated by an increase in the fluorescence intensity.

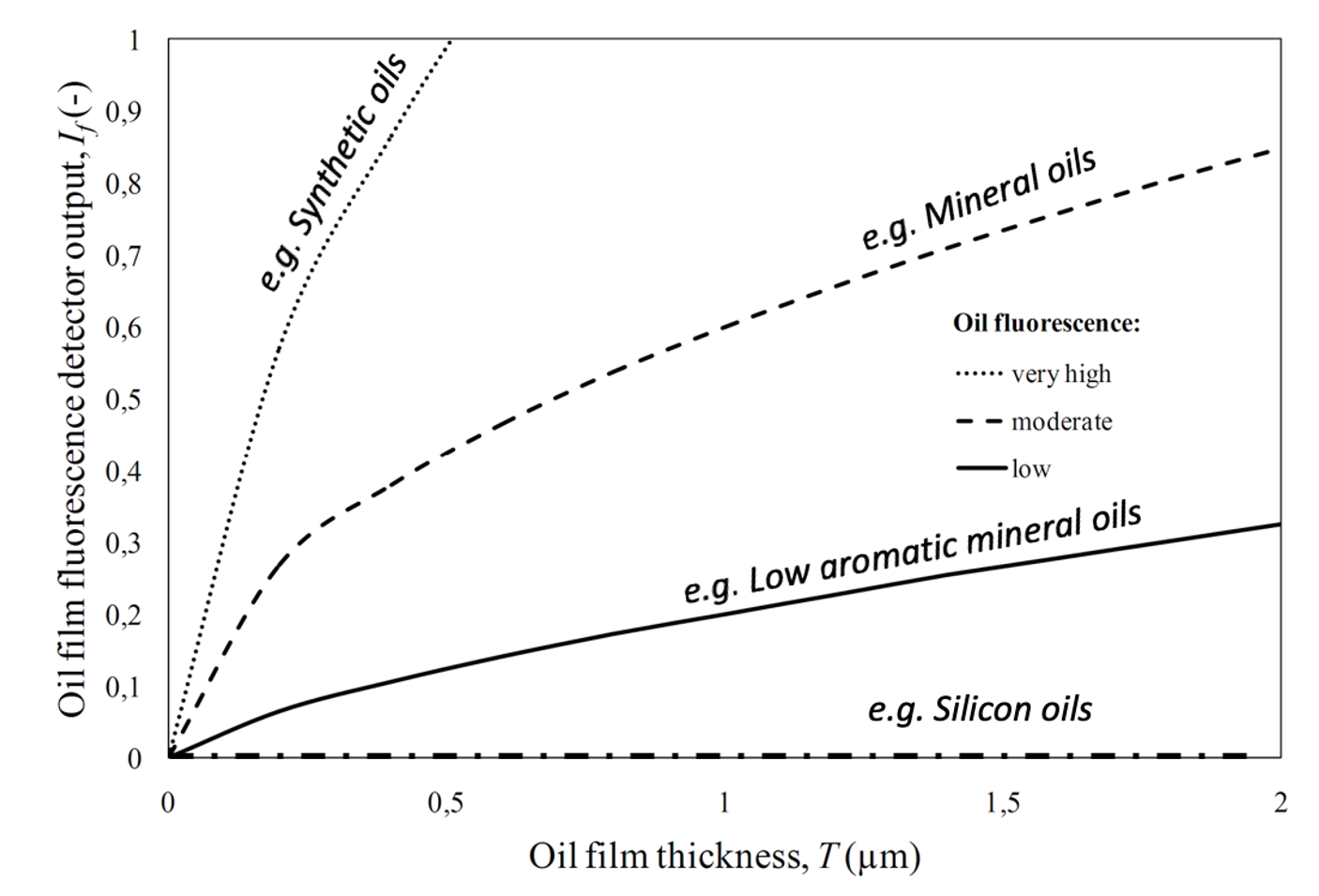

Recognoil® PRO software enables automatic conversion of the fluorescence value to layer thicknesses [nm],

resp. area concentration [mg.m-2] using a physical-mathematical model of oil made by laboratory sampling calibration.

Control of processes associated with the intentional formation of thin layers on the surface of products brings not only

improved process from the technologist's point of view, but it also enables a significant reduction in the consumption of process fluids,

a reduction in scrap and an improvement in workplace conditions.

From the fluorescence map, you can immediately find out whether the created layers are even and uniform.

By objective and quantifiable evaluation of the surface condition of the parts, the optimal amount of applied oil films can be achieved for both lubrication and preservation processes.

FAQ

In order for the results of Recognoil® products to be trusted, they must be correctly interpreted by the operator.

Therefore, it is important to know the basic principle of operation of devices and the correct principles of their use.

For this reason, we have created a background for users, which we are constantly updating -

Recognoil® Measurement Guide .

In it, the user will find individual methodological procedures for various applications and the basic evaluation of the surface condition on the basis of the obtained data.

The most frequent questions are:

Recognoil® products have already helped to increase production quality and product reliability

in more than 70 companies around the world. The company TechTest, s.r.o. in addition,

has experience in the development and production of equipment for the detection of grease directly according to the client's requirements,

whether for example in fully automated lines or for operator control of internal surfaces of pipes and other hard-to-reach areas.

Important references:

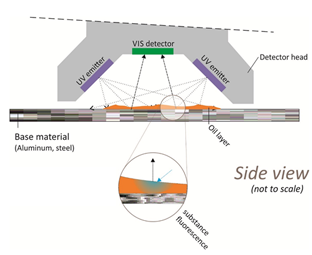

The devices developed by us irradiate the surface with invisible and undetectable rays of UV light.

This radiation has a higher energy than visible light and can thus excite some substances to emit light in the visible spectrum, which can be easily detected.

This physical phenomenon is called fluorescence. Most fatty substances exhibit this phenomenon,

and therefore the instrument measures the intensity of fluorescence emitted by the substance on the surface of the object.

As mentioned above, the detector receives the results of a fluorescence process that is already in the visible light range.

This implies the need to shield the scanned area from the surrounding environment, in which the visible light is of course located and thus affects the exposure results.

For accurate results, 100% shading from ambient lighting is required.

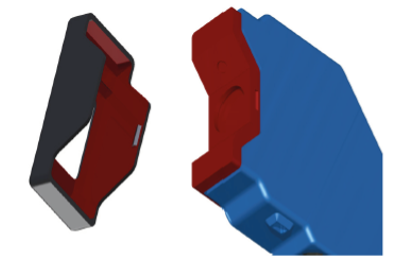

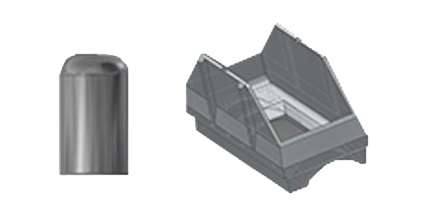

In the case of Recognoil® 2W, the shading of the environment is solved by means of an exchangeable adapter. It is supplied as standard for flat surfaces. In addition, the shape and size of the adapter ensures the correct distance between the scanned surface and the detector. Scanning of complex surfaces, chamfers, small radii and scanning of spatial objects is therefore performed using special adapters in the form of a negative of the scanned surface. We produce these adapters using the 3D printing method on the basis of documents supplied by the customer.

For example, a shaped adapter is necessary for the correct measurement of cylindrical surfaces.

The described limitations due to the shape and size of the object are eliminated when using the Recognoil® QB device, where I scan the object completely contactless and shielding is achieved by placing the object on the measuring table in the dark space of the box.

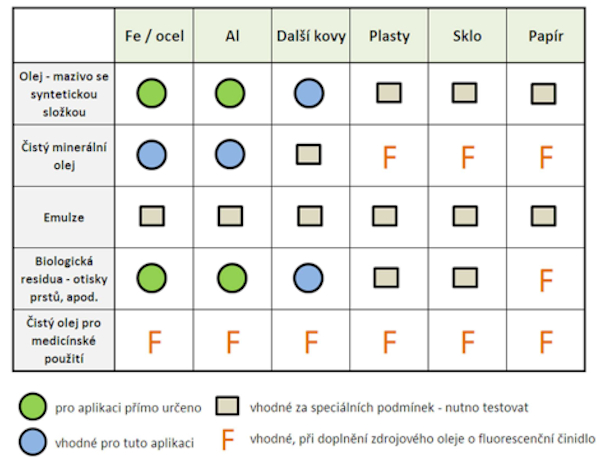

Recognoil® products from TechTest, s.r.o. were developed primarily for the detection of fatty substances on metallic materials.

It can be used for all types of lubricants and oils, with a few exceptions.

They are not suitable for silicone-based oils. In addition to the mentioned oils and lubricants, which can be easily detected by this principle,

they exhibit fluorescence, for example: dust, paper, plastics, etc. These contaminants are thus also able to be detected by our products.

Suitable base materials are mainly metals (they do not show fluorescence). The device can be used on plastics, glass, ceramics, etc.

based on verification of the properties of the material (or its composition, surface treatment, etc.).

Unfortunately, the fluorescence method used in Recognoil® products is not a universal method in the sense of unpacking - measuring.

Before purchasing, we recommend that you properly discuss your required application with us and best test it on a real sample of your products.

In order to provide the customer with enough information about the suitability of our products, we often need to ask for the following information:

We will then design a specific product for the customer and offer to perform a free test of the suitability of Recognoil® for the required application.

The essence of the detection principle is the induction of luminescence of contaminants, its capture and subsequent evaluation using the supplied software.

The standard output is the so-called fluorescence intensity [F.U. - fluorescence units] resp. its mean value related to the measured area and image output -

fluorescence map showing the distribution of impurities on the surface of the part.

Yes. Conversion of the detector output to the surface concentration of the oil layer [mg.m-2] or the film thickness [nm] is possible thanks to the software function, but it requires the import of a physical-mathematical model of oil made by laboratory sampling calibration.

Yes, both offered products Recognoil® 2W and Recognoil® QB are equipped with a set of LEDs

and sound signaling allowing separate measurements without the need to connect to a PC or tablet with the possibility of determining

the permissibility of surface contamination according to a preset limit. The pictograms on the LED panel are used for visual orientation of the operator.

The operator can have 3 limits loaded in the device (for various surfaces, technological steps, etc.),

which he can activate using the multifunction button of the device trigger. In addition, all exposures are stored in the device's memory -

the operator has the option to download full-fledged images, make reports, etc. It is also possible to ensure the sending of measured data

to the internal network or other specific functions according to individual customer requirements.

No. Recognoil® products do not allow to determine the value of surface tension in mN.m-1 from the principle of the method of detection of greasy pollution.

However, it is possible under suitable conditions to determine in the laboratory the value of the surface tension corresponding to the value of the output of our devices,

ie the fluorescence intensity.

For specific applications, it is not possible to set in advance a surface contamination limit value [F.U.] suitable for the intended application.

The determination should be based on validation tests. On the contrary, it is very easy to determine the value of F.U. for perfectly degreased metal surfaces

(this should always be as low as possible and ideally the same over the entire surface).

Yes, it must be taken into account that different types of oils show different fluorescence (due to their nature, additives, etc.).

It is therefore not possible, for example, in the case of values of 10,000 F.U. one oil and 100,000 F.U. the other without laboratory calibration

to talk about different layer thicknesses or surface concentrations. Due to the nature of the detection method,

these values must always be determined using a mathematical model of the oil on the basis of laboratory calibration.

The graph below shows an example of the behavior of individual oils in terms of fluorescence intensity depending on their nature and film thickness.

When working with the Recognoil® according to the instructions in the user manual, there is no risk associated with exposure to UV radiation.

Recognoil® devices are equipped with 2-level protection of the operator against unwanted exposure to UV radiation.

The Recognoil® 2W device checks the shading of the detector - ie whether it is attached to the object.

At the same time, it is only used in combination with suitable measuring adapters to ensure complete shielding of UV radiation.

Furthermore, the box is equipped with a magnetic sensor closing the working space.

At the same time, during the exposure, the operator is separated from the radiation source by the walls of the box.

Recognoil® instruments come with a factory calibration protocol.

Reproducible results over a long period of time should be ensured if the device is stored and maintained properly.

To verify the condition of the device itself, it is possible to order purity standards and calibration samples.

To ensure stable and reproducible results, we recommend that you send the device at least once a year for regular maintenance

(cleaning of optical elements, restoration of anti-fluorescent coating) and control calibration (output calibration protocol is included).

The basic benefits of Recognoil® products can be summarized in the following points:

In addition, the acquisition of Recognoil® can be considered a meaningful investment with a high return:

Yes, in some cases we are able to offer a completely unique device for the detection of contaminants according to the specific requirements of the client.

For example, detection of greasy impurities on the inner walls of pipes, or devices for searching for dactyloscopic traces.

We also have experience with fully automated measurement or with the production of hand-held devices or single-purpose devices for operators.

We also offer customization of the supplied software according to customer requirements QR code, etc.).

Yes. The company TechTest, s.r.o. offers laboratory testing of your products Recognoil® products

We also provide consulting services in the field of surface treatment and field measurement.

We also create measuring adapters and customized products for customers for in order to streamline and refine the parts inspection process.

Objectively evaluate changes in technological parameters, quality of production, suitability of some technologies, production operations,

condition of process fluids and media during their life cycle and a number of other parameters related to the processes of cleaning,

degreasing or application of oil films. from Recognoil® products to production allows you to control inputs, processes and their outputs.

This makes it possible to significantly reduce the scrap rate of production, increase its economy,

reduce the environmental impact and streamline the entire production process.

We believe that Recognoil® products are here for those who have customers and quality. On first place!

Verification test of the suitability of Recognoil® products, when the customer sends about 3-5 parts for testing, we perform them free of charge.

We will then send a report on the results obtained during the measurement and recommendations regarding the possible application of the device

(eg the need to use special adapters or fixtures due to the shape of the object, etc.). use. We will verify whether the shape,

material or type of contaminant is suitable for our detection method.

When packaging samples, it is primarily a matter of preventing contamination of the surface with the packaging material.

It is best to wrap the test sample in a foil and to prevent contact of the product surface with this foil by means of spacers.

You can also use suitable plastic or metal boxes or other products to ensure that the inspected sample area does not touch the package or other inspected part.

Don't pack samples in paper towels! Don't use other textiles. The fibers of these materials are detectable with Recognoil® products

and would therefore affect the evaluation of the surface condition.

The better you pack your samples, the more objective the results we will achieve.

Examples of the use of Recognoil® products

Surface treatment

Quality control of degreasing of a surface contaminated with oil after previous forming operations.

The operator immediately determines the permissibility of the surface after degreasing.

At the same time, it determines if the degreasing process is set correctly.

The operator can use the preset for a given part and determine the suitability of the surface only on the basis of OK / NOK information.

Technology selection - method of setting the limit

Determination of the detection limit based on the test of adhesion of the paint coating.

The technologist, together with the quality controller, evaluates the adhesion of the coating based on the degree of surface pretreatment.

They evaluate individual pre-treatment methods (mechanical, chemical and plasma) and at the same time compare various process parameters (time, temperature, medium, etc.

).

Thanks to the use of Recognoil® surface of the part before and after the pretreatment process and can thus objectively evaluate the effect of the degree of surface purity on the resulting adhesion of the coating.

In addition, the performed test determined the lithium values for the OK / NOK preselection.

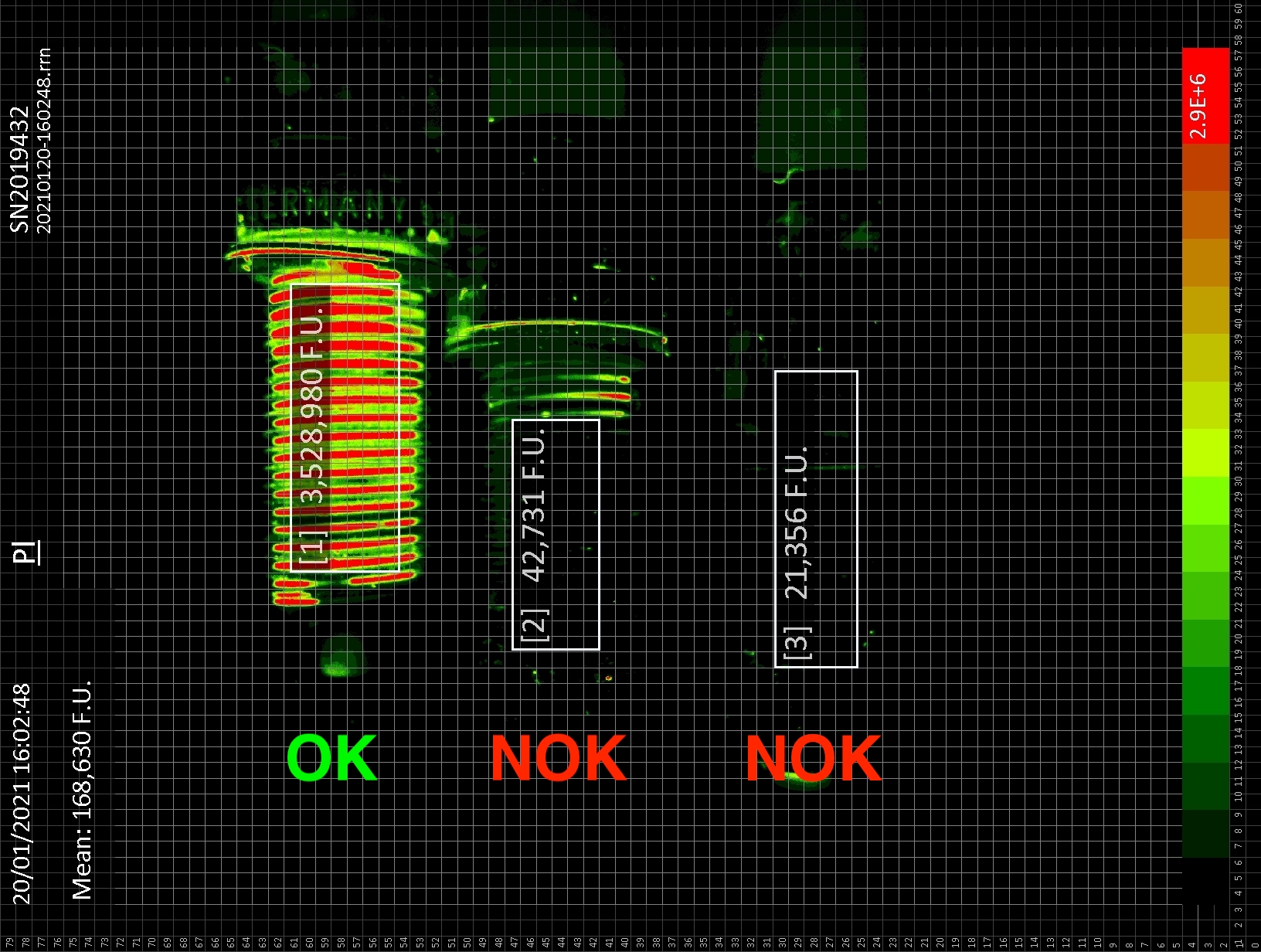

Controlled application of oils

Determination of the required amount and even distribution of the oil film.

Whether for the preservation of parts as a form of corrosion protection or for the application of oil films for lubrication, Recognoil® products allow you to determine the optimal film thickness.

Again, by visualizing the actual distribution of oil on the surface, homogeneity of the film and thus ensure an efficient and controlled method of its application.

Conservation of specific surfaces

Verification of correctly performed conservation of the part.

Before packing the parts, the operator checks the correctness of the performed conservation of critical areas of the part. The inspected area has a defined minimum permissible value of fluorescence intensity.

Thanks to area scanning, the operator can assess whether the required area is preserved evenly and in the required amount.

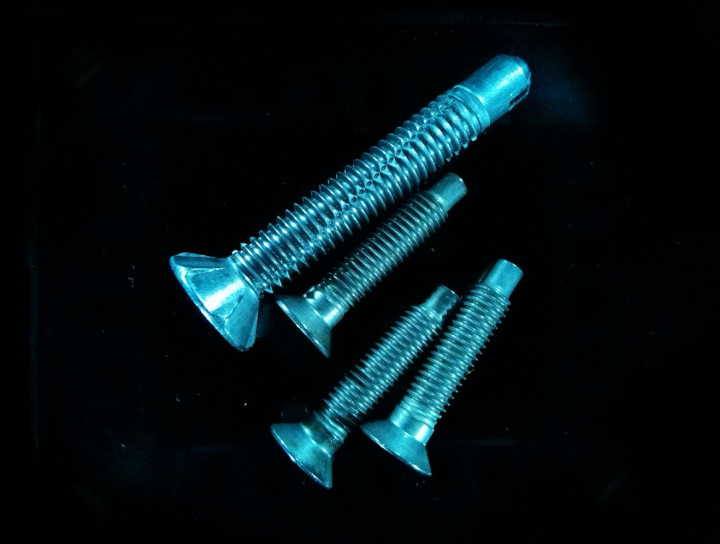

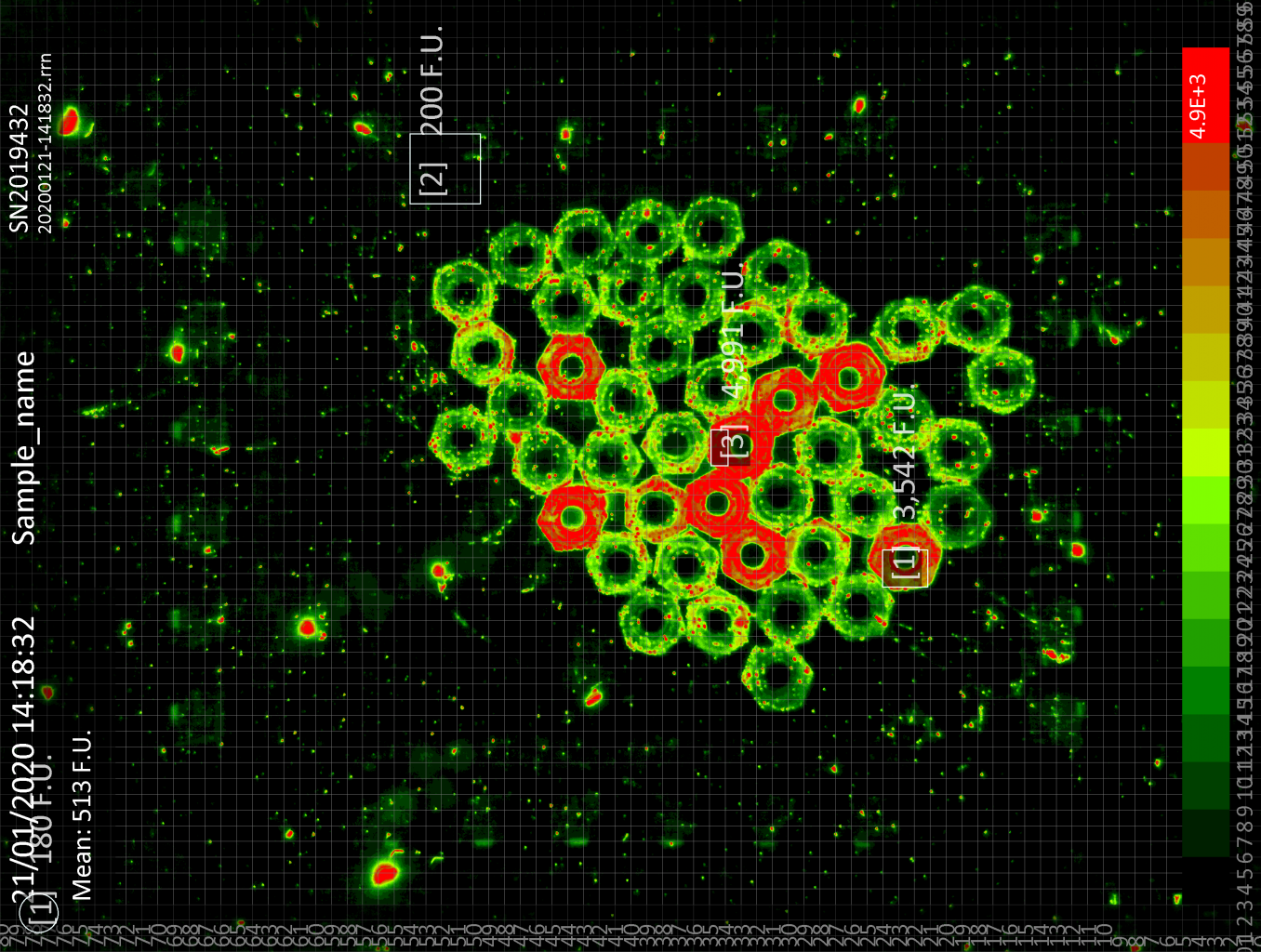

Inspection of small parts

Mass method of determining the surface condition of small parts.

Recognoil® products enable mass inspection of the surface condition of small parts.

In addition, the supplied software can be equipped with functions such as automatic object recognition, insertion of evaluation masks or automatic selection of inadmissible pieces according to specific customer requirements.

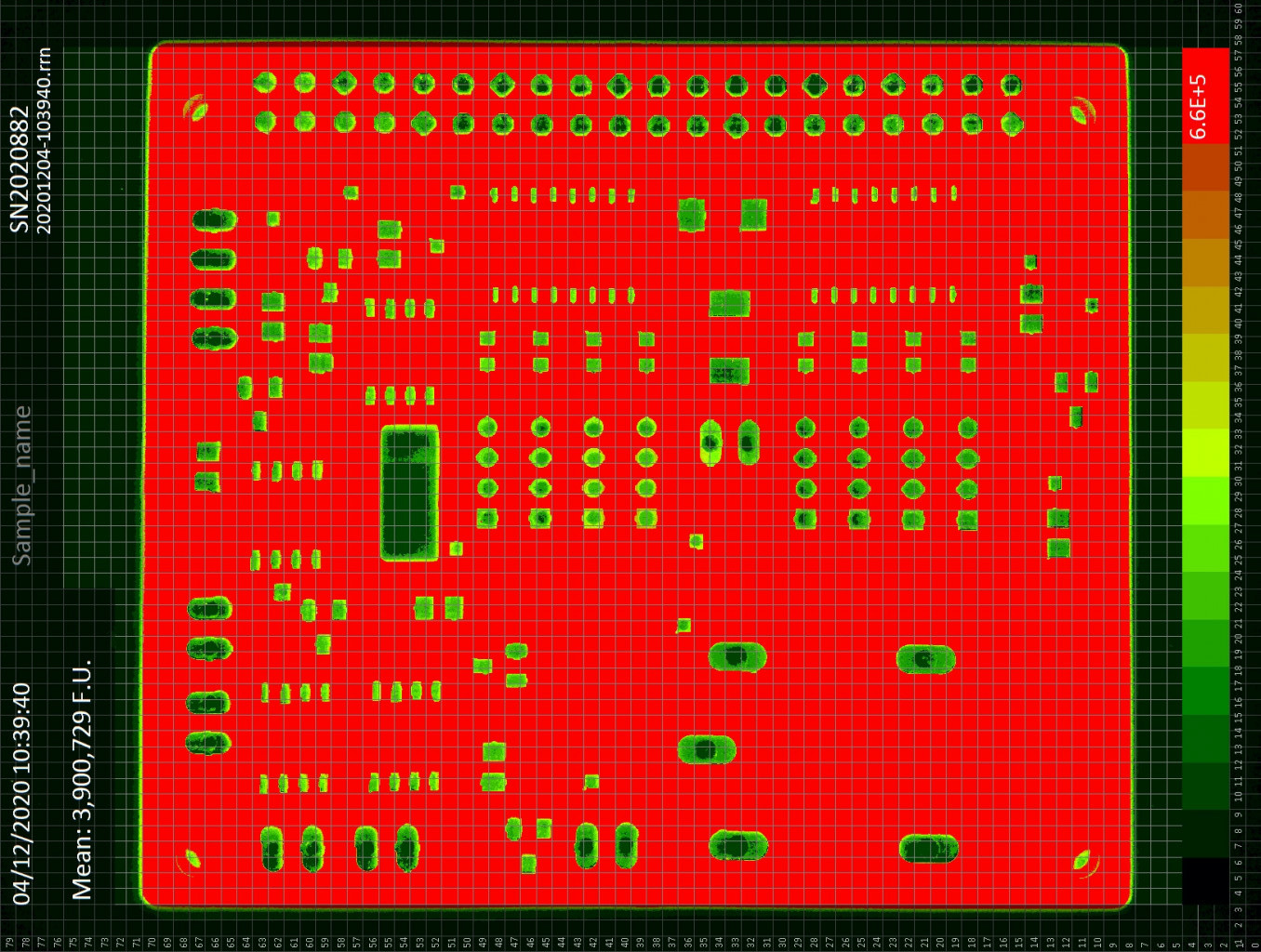

Printed Circuit Board testing

Checking the cleanliness of the soldering surface and detection of flux residues.

For printed circuit boards, it is important to achieve high cleanliness of soldered surfaces to ensure a strong and electrically conductive connection.

Recognoil® products not only enable the control of the cleanliness of these surfaces, but can also detect unwanted flux residues.

Evaluation of blasted surfaces

Determination of surface and abrasive effectivity.

With Recognoil® products, it is possible to detect not only greasy substances on the blasted surface, but also other foreign impurities such as dust, paint residues, textiles and other foreign substances.

The advantage is that the quality and condition of the abrasive can also be checked. This allows you to have complete control over the blasting process.

Revealing technological indiscipline

Evaluation of surface quality before welding, soldering and gluing.

Perfect surface preparation is crucial for the quality and correct strength of the joints of metallic materials.

With Recognoil® products, you can not only detect residual impurities, but you can also detect technological indiscipline - for example, the use of separators for welding on hot-dip galvanizing structures.

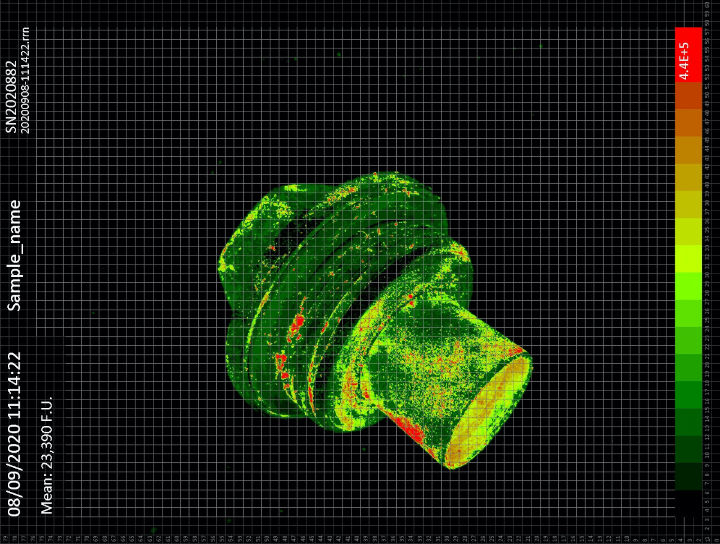

Contactless detection of complex objects

Easy inspection of shaped surfaces.

Recognoil® QB can immediately inspect complex objects, such as gears, castings, 3D printing parts, etc., without any surface preparation.

In addition, we are able to recognize Recognoil® products to modify and we can offer individual tailor-made solutions (for example, for the detection of the inner surfaces of pipes and other hard-to-reach areas).

Published articles

We understand surface treatments and engineering technologies.

Our team has many years of experience and knowledge not only from the academic environment, but also from industrial practice.

That is why we often do not only sell our clients equipment for controlling their processes, but we also become a partner for them in decision-making processes or in solving problems

associated with the detection of impurities.

We regularly publish in domestic professional periodicals and participate in conferences in the field of surface treatment.

Below you will find a list of articles related to the detection of Recognoil® impurities published in indexed databases.

Freely available articles about our products and their use can be found, for example, in magazines MM Spektrum, Technický týdeník and Povrcháři.

Contact

Are you interested in Recognoil® products? Are you interested in our services?

For more information do not hesitate to contact us at any time!

+420 774 452 995 - Ing. Petr Chabera

+420 724 234 699 - Ing. Michal Zoubek

+420 605 868 932 - Ing. Jan Kudlacek, Ph.D.

+420 605 305 171 - Ing. Jakub Svoboda

TechTest, s.r.o. - Headquarters

Jungmannova 917

285 04 Uhlirske Janovice

CZECH REPUBLIC

TechTest, s.r.o. - SERVICE & RECEPTION

Jungmannova 917

285 04 Uhlirske Janovice

CZECH REPUBLIC

TechTest, s.r.o. - Administrative address

Semonice 110

551 01 Jaromer

CZECH REPUBLIC